Aerospace

Performance-critical resistors for the most demanding space and satellite applications

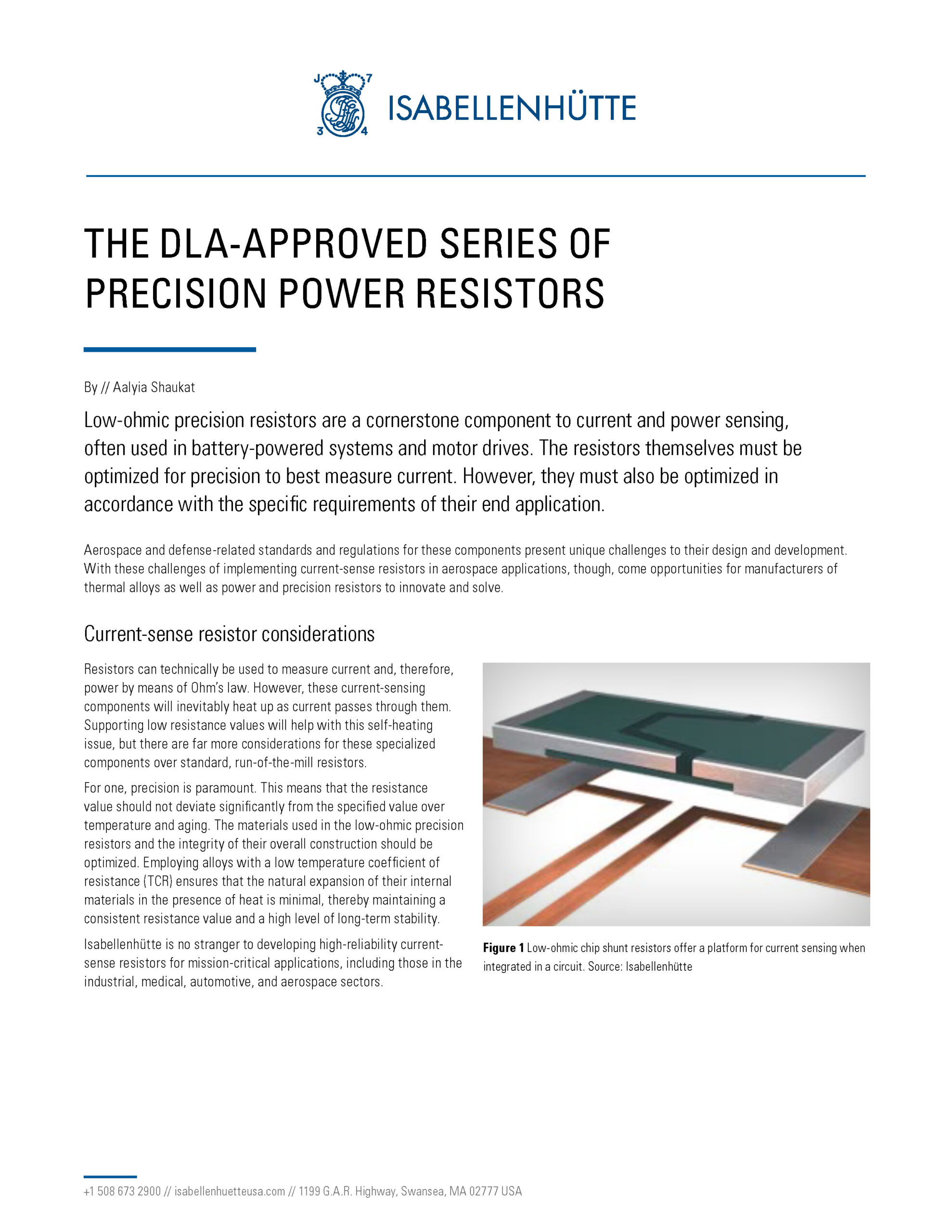

We supply hundreds of DLA, NASA and ESCC-qualified components to the top names in aerospace across three continents. As a trusted supplier with decades of mission-proven experience, our customers rely on our deep metallurgical knowledge to help them solve the unique challenges of deep space operation.

Packing more power into tighter footprints while maintaining low TCR is a constant and evolving effort—one that our resistors, shunts, and sensors continually master. We understand the uncompromising tolerances that support the highest quality, safety, longevity, environment, and performance demands faced by aerospace and satellite pioneers.

See how our complete control over production—from smelting proprietary alloys to customizing fast-tracked designs—sets us apart in serving the aerospace market.

| Model | Mounting Style | Resistance Range (Low) | Resistance Range (High) | Wattage | TCR (ppm/K) | Package Size | Specification | Product Details |

|---|---|---|---|---|---|---|---|---|

| SMP-PW | Surface Mount | 0.005 | 1 | 1 | 50 to 100 | 2010 | ESCC 4001/027 | View More |

| SMS-PW | Surface Mount | 0.005 | 1 | 2 | 50 to 100 | 2512 | ESCC 4001/027 | View More |

| SMT-PW | Surface Mount | 0.004 | 4.7 | 3 | 50 to 100 | 2817 | ESCC 4001/027 | View More |

| SMV-PW | Surface Mount | 0.0033 | 1 | 3 | 30 to 50 | 4723 | ESCC 4001/027 | View More |

| VMI-M | Surface Mount | 0.01 | 0.05 | 0.5 | 30 to 50 | 0805 | DLA 25003 | View More |

| VMK-M | Surface Mount | 0.01 | 0.47 | .75 | 20 | 1206 | DLA 25004 | View More |

| VMP-M | Surface Mount | 0.005 | 1 | 1.5 | 20 | 2010 | DLA 25005 | View More |

| VMS-M | Surface Mount | 0.005 | 1 | 2 | 20 | 2512 | DLA 25006 | View More |