PRECISION ALLOYS

The only metallurgy challenge we haven’t conquered in 500 years – is your next one

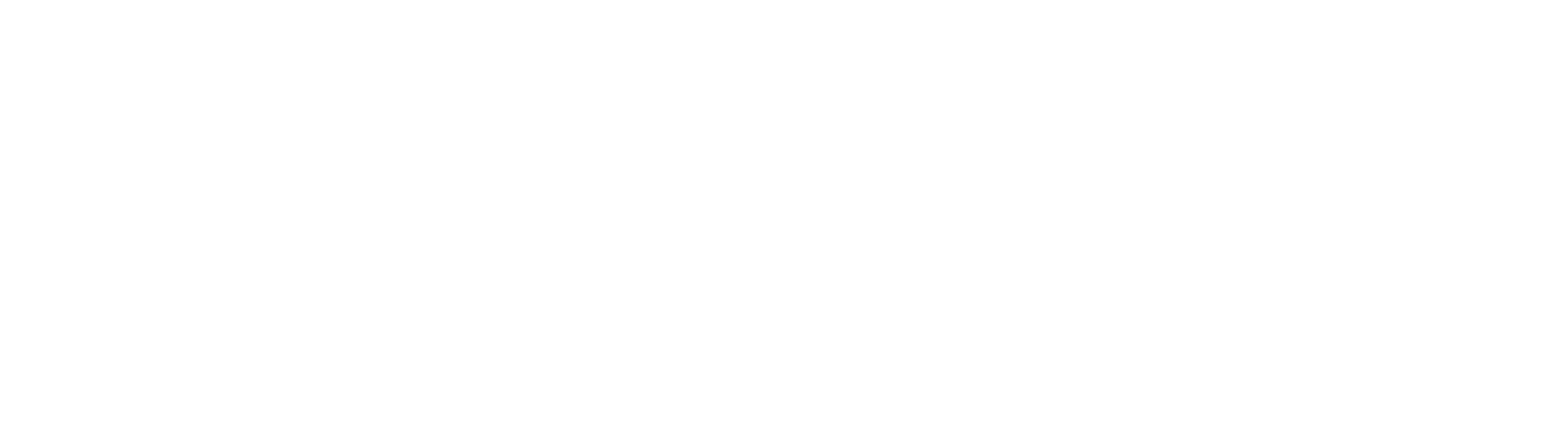

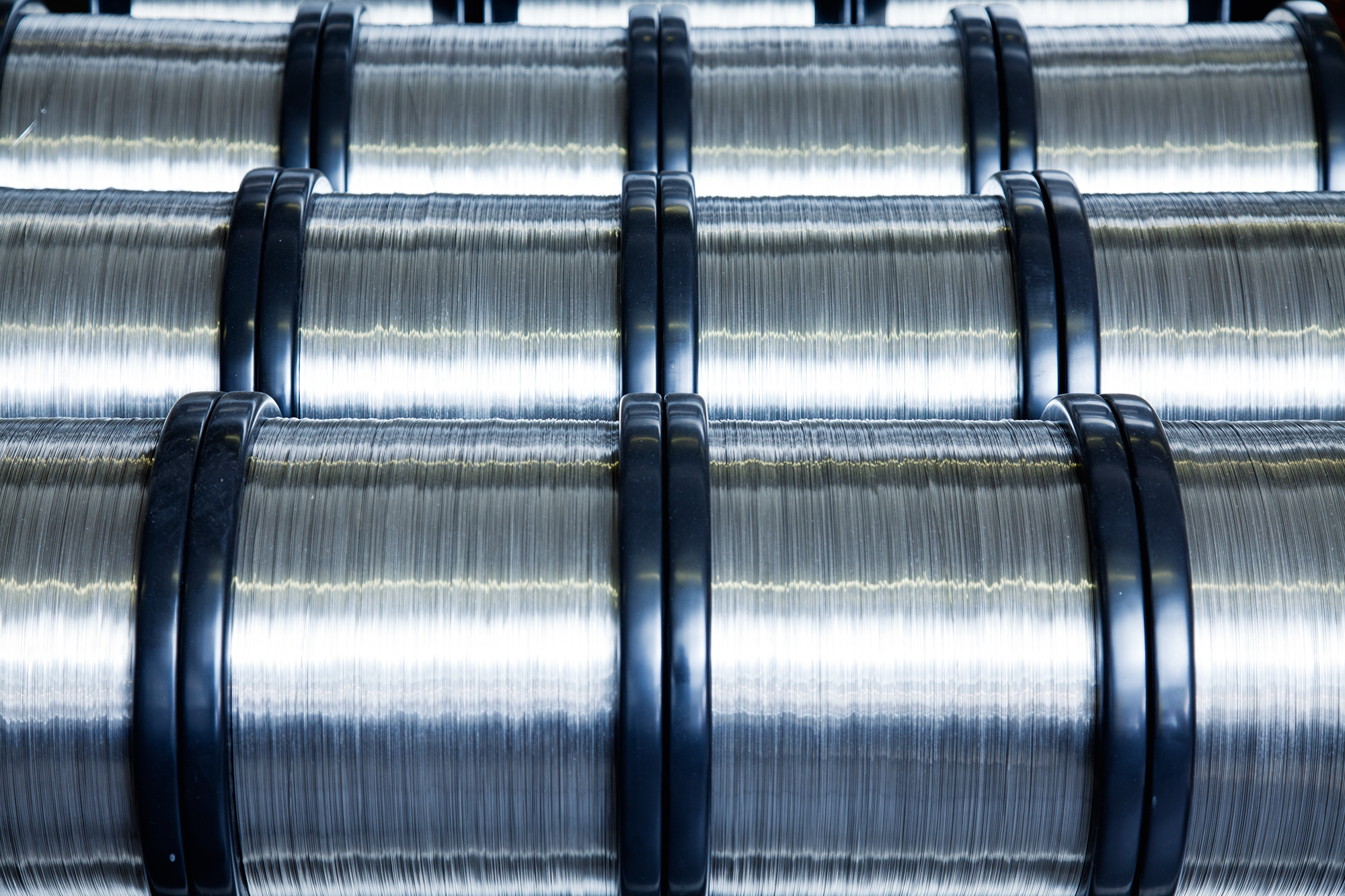

By tradition, our alloys have satisfied the most exacting tolerances —in compliance with all national and international standards. By temperament, we are innovators who embrace a challenge—rising to meet individual demands and the highest performance requirements. Our continually expanding line of products and capabilities include soft annealed wires (down to 7 microns), strips, rods, flat wires in standardized or customer-specific construction.

THERMOELECTRIC ALLOYS

We offer alloys for internationally standardized thermocouples (also mineral insulated) as well as extension and compensating leads for producing thermocouples, quick cups, connectors and plugs. Solid, stranded and flat wires, strips, foils and rods available. Our broad range of thermoelectric alloys comprises types K, J,T, E, L and U—along with alloys for compensation leads for types B, C, D, R and S.

- RAlloys for thermocouples, thermoelectric leads and compensation leads

- Temperature range from -40°C to + 1,200°C

- Compliance with all common international standards

- Special requirements with regard to thermoelectric voltage and dimensional tolerances or special thermoelectric voltages, e.g. for mineral-insulated wires, can also be fulfilled

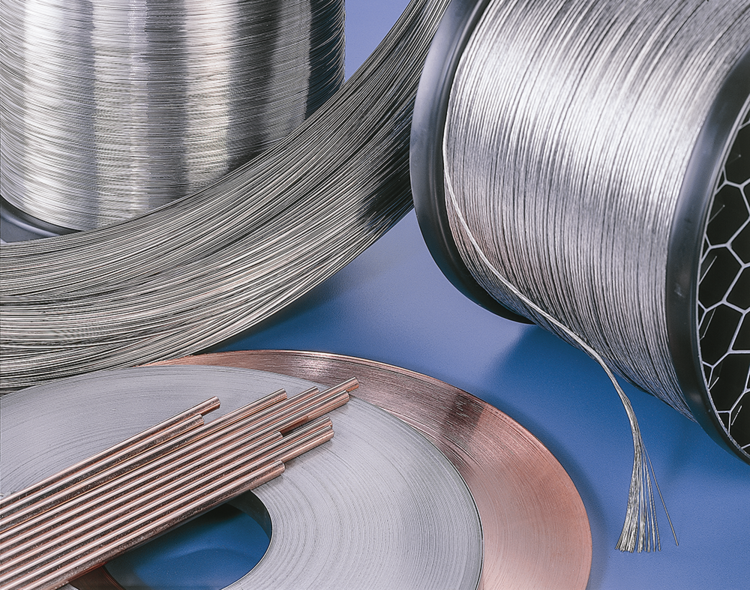

RESISTANCE ALLOYS

Our resistance alloys are used in many areas of electronics and electrical engineering and can be supplied in many different forms and types. Our alloys MANGANIN®, ZERANIN®, ISAOHM® and NOVENTIN® are homogenous solid-solution alloys that are annealed and stabilized in the primary thermodynamic state—guaranteeing stability values in the ppm range per annum.

- 15 Watts permanent power

- Made from electron-beam welded composite

- Soldering temperatures up to 350°C/30 secs or 250°C/10 mins

- High permanent and pulse power rating

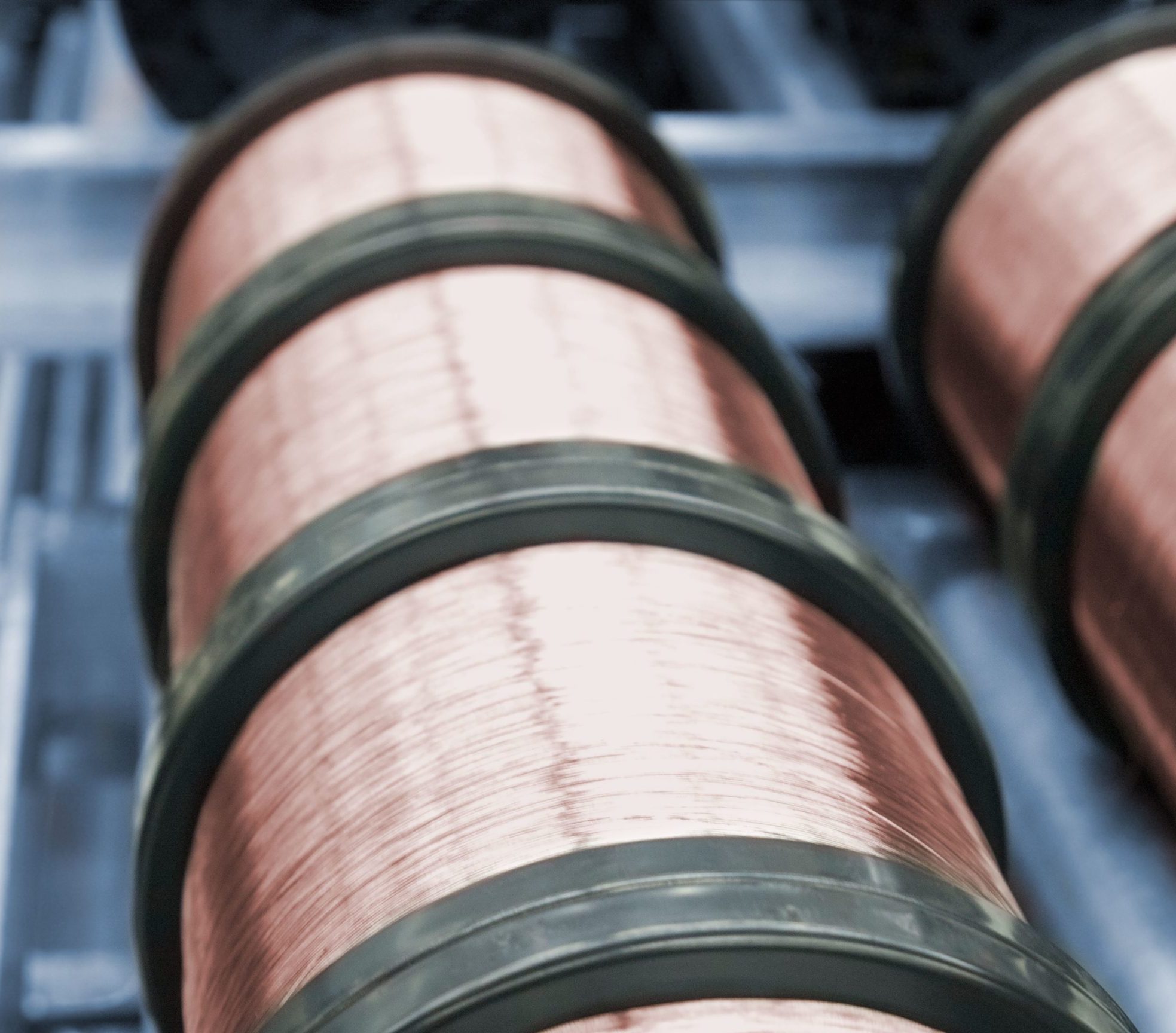

HIGH STRENGTH ALLOYS (CuCr)

We offer a variety of options that allow circuit designers and engineers tremendous flexibility in materials and properties for joining and bonding, including:

ISA-BRAZE® — High-temperature brazing alloy

CuMn12Ni (Manganin®) Offering less splatter than standard wires for arc applications, ISA-BRAZE is ideal for fluxless brazing using shielding gases. Good for gap, joint, and resurface brazing, it may also be used as a functional material for coatings. Using ISA-BRAZE®, all kinds of steels (e.g. nickel alloys, chromium, molybdenum, tungsten) can be joined or then coated.

TYPICAL APPLICATIONS

Aerospace

Long-term safety and reliability for the most sophisticated—and demanding—applications.

Automotive

Fit more technology into limited spaces within cost and performance parameters.

Industrial

From factory automation, to performance-driven consumer goods, we support bold innovation.

Medical

Supporting life-saving advances with compact technology and long-term reliability.