PROBLEMS WE SOLVE

Expect more – when it really matters: in the real world

Technological, scientific, and engineering experience are important to have, but nothing compares to proving your performance under actual conditions. With literally centuries of proven product excellence in the field, we are proud to share our more recent successes in solving some urgent challenges for our customers across a broad spectrum of applications and industries. Within each of the challenges listed, you’ll find examples of how our products and teams come together to deliver more.

TECHNOLOGY CHALLENGES

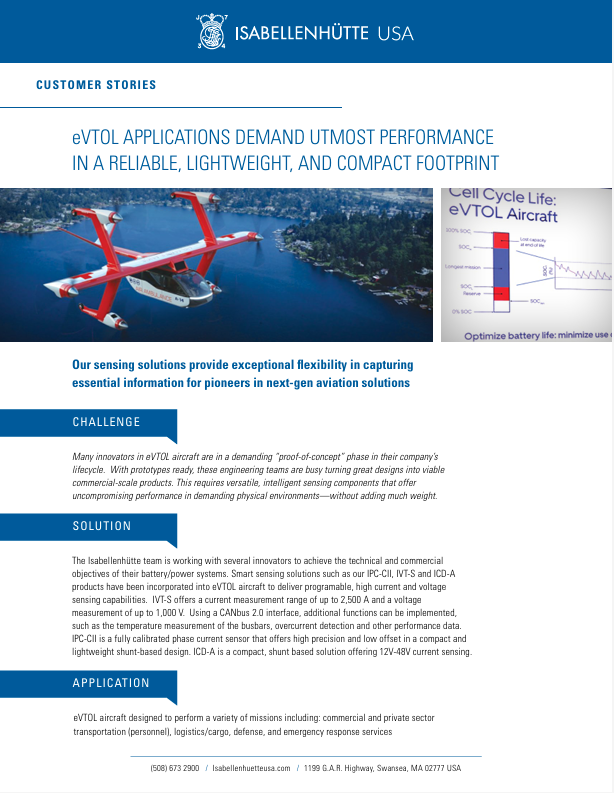

ACCURACY

From measuring the lowest resistance tolerances, to accommodating extremes in temperature variations, our components—and the alloys they’re made from—support uncompromising accuracy and have earned us “best-in-business” status for measuring voltage, current and temperature.

LONG-TERM STABILITY

Our alloys and components support products designed to last.

Our annealed and stabilized resistance alloys safeguard your products from corrosion and metallurgical structure changes that affect performance over time.

POWER DENSITY

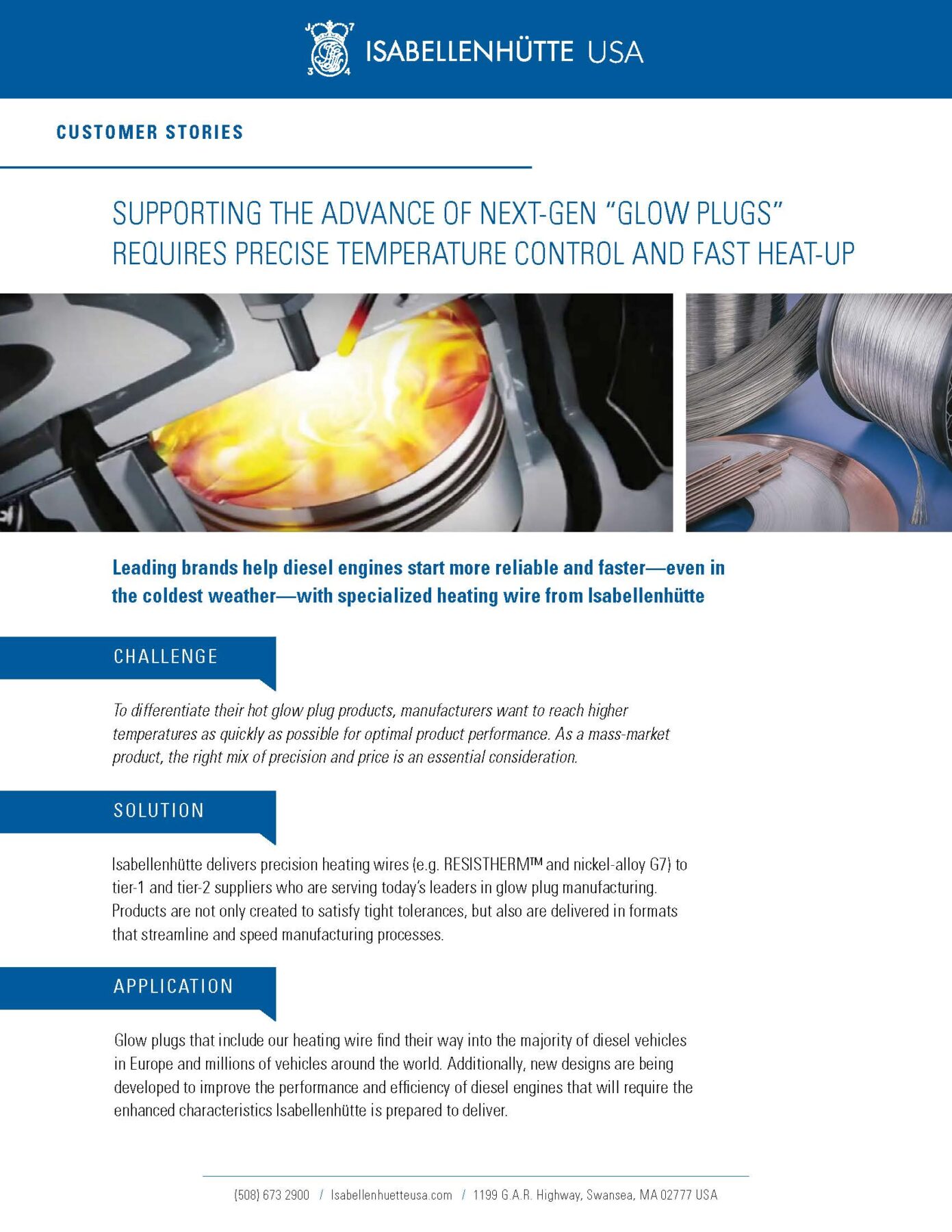

The drive to pack more power into smaller footprints presents critical challenges for maintaining reliable performance. Supported by our proven alloys, our solutions lead the industry in power rating to help you save space and safeguard performance.

STREAMLINING

Designing solutions that accomplish more in ever-decreasing spaces is a common challenge across industries. Our measurement products bring you the ability to combine multiple sensing functions (e.g. current, voltage, temperature) in a single device.

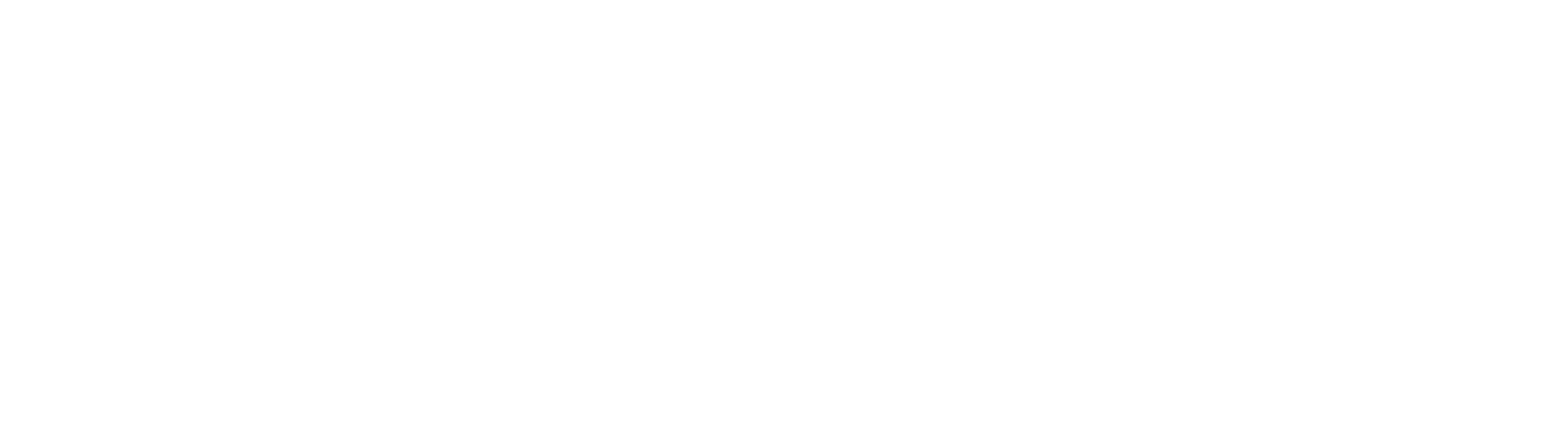

THERMAL MANAGEMENT

Maintaining temperature independence requires exacting attention and precision in component materials and construction. Isabellenhütte innovations such as using a thermally-conductive adhesive to bond resistance foil to substrates help our customers achieve higher thermal capacity and greater power dissipation.

TYPICAL APPLICATIONS

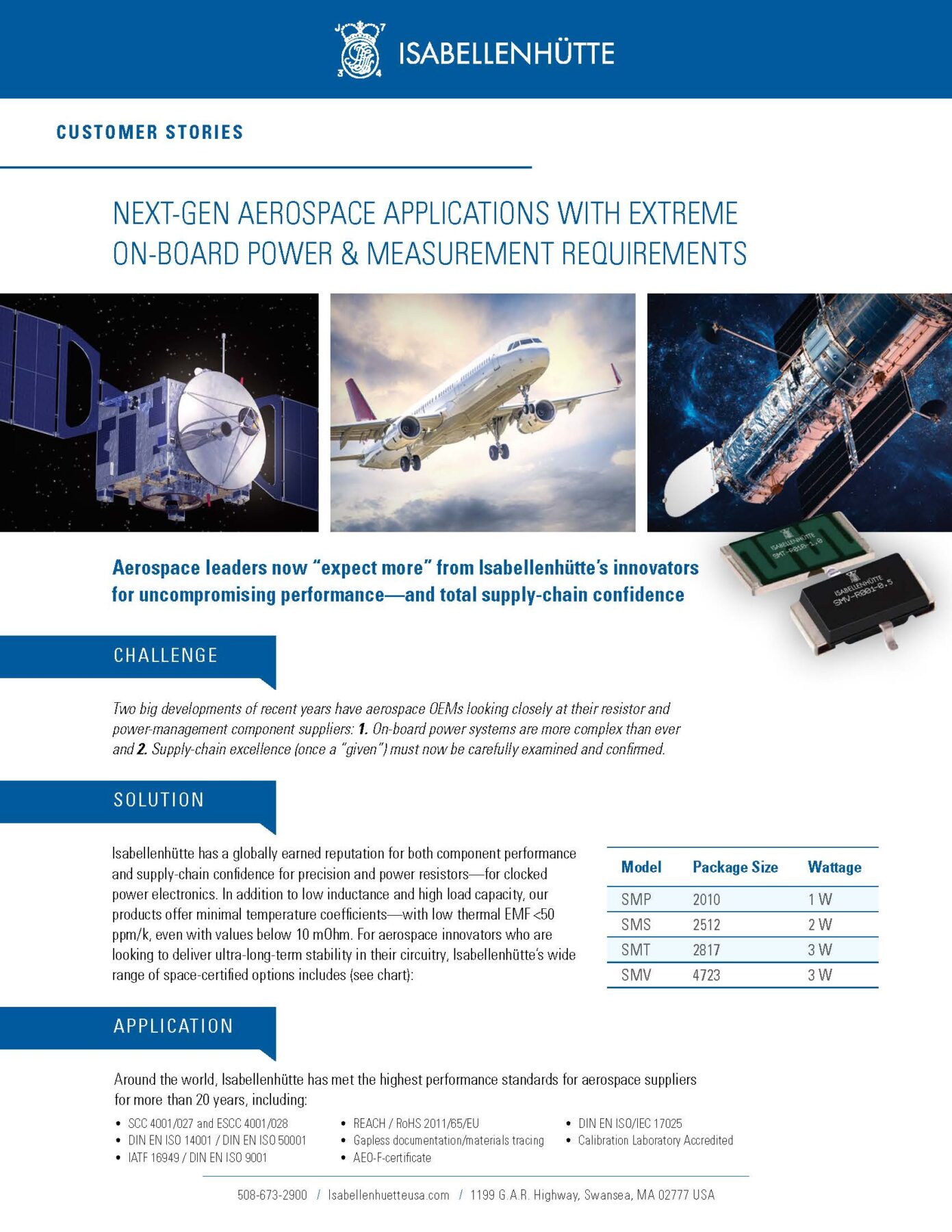

Aerospace

Long-term safety and reliability for the most sophisticated—and demanding—applications.

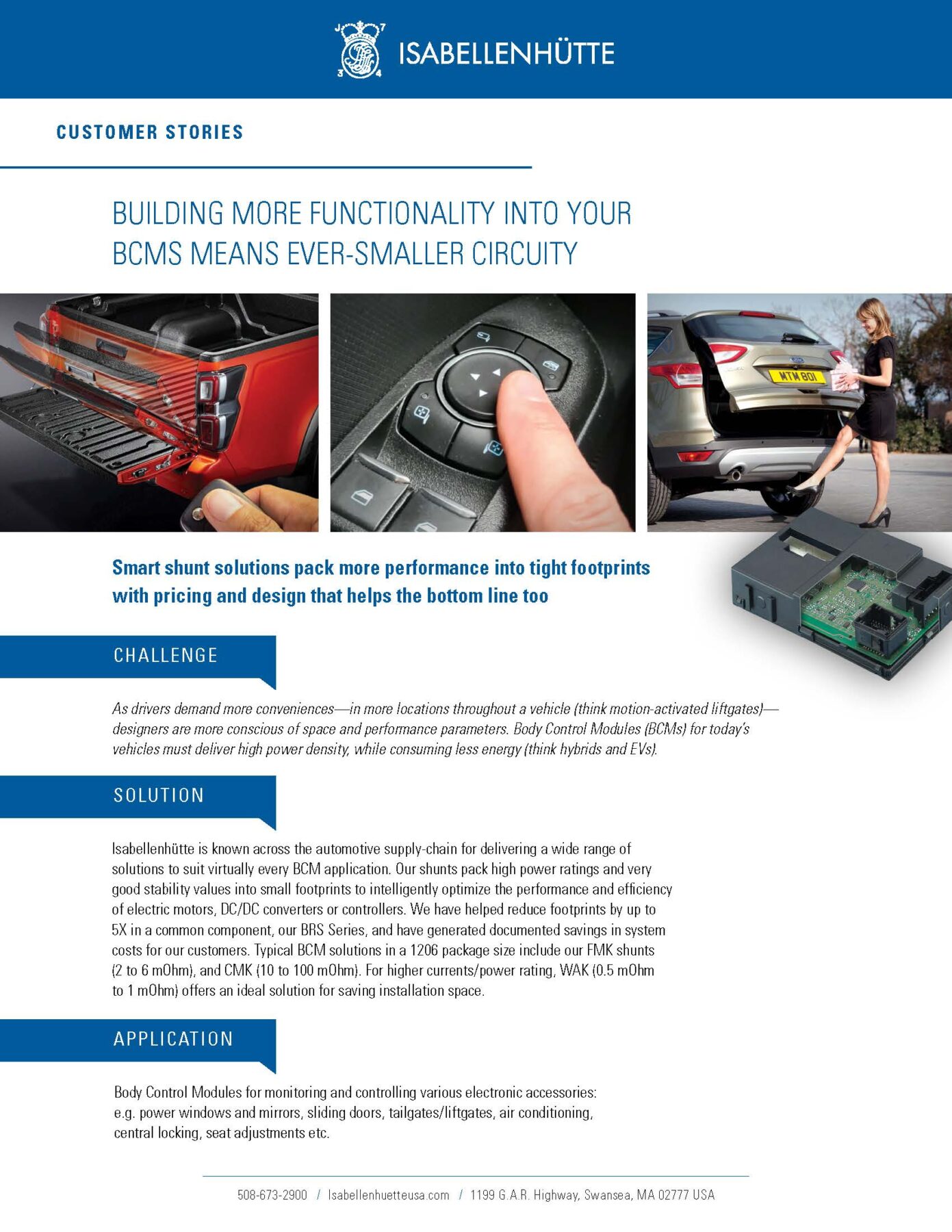

Automotive

Fit more technology into limited spaces within cost and performance parameters.

Industrial

From factory automation, to performance-driven consumer goods, we support bold innovation.

Medical

Supporting life-saving advances with compact technology and long-term reliability.